hardness test hrc full form|how to calculate rockwell hardness : exporting HRC: It’s a measure of hardness determined by using a diamond cone press and applying a 150kg load. This scale is used for materials that have high hardness, such as quenched steel, etc. In addition: (1) HRC stands for . Resultado da Calculamos as derivadas das funções trigonométricas inversas usando a derivada da função inversa: Arco-seno: y = arcsenx ⇐⇒ x = seny com − .

{plog:ftitle_list}

Resultado da MEILLEUR PRIX GARANTI. Nous garantissons et égalisons les prix les plus bas sur le marché. GRAND CHOIX DE PNEUS ET ROUES. Retrouvez les .

HRC: Uses a 150kg load and a diamond cone indenter to determine hardness, and is used for materials with very high hardness (such as hardened steel, etc.). Additionally: HRC implies Rockwell hardness C scale.

HRC: It’s a measure of hardness determined by using a diamond cone . A Rockwell hardness tester. The Rockwell scale is a hardness scale .

HRB: It is the hardness obtained by using a 100kg load and a hardened steel ball with a diameter of 1.58mm, which is used for materials with lower hardness (such as annealed .

HRC: It’s a measure of hardness determined by using a diamond cone press and applying a 150kg load. This scale is used for materials that have high hardness, such as quenched steel, etc. In addition: (1) HRC stands for .The most common Rockwell method in practice is HRC. In principle, ball indenters are used for the hardness tests on softer materials and diamond indenters for testing harder materials. The diamond would destroy softer .Learn more about hardness testing basics here. The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and understand the .

Hardness is a metric that measures a material’s resistance to local deformations, such as plastic deformation, indentations, or scratches. It is a crucial factor in determining the hardness of a material. Types of Metal .Rockwell hardness testing is a useful and efficient way to determine the hardness of a material. It measures the depth of penetration of an indenter on the material being tested, making it possible to calculate its relative hardness and .These are a numeric number representing hardness, two letters “HR”, abbreviations representing “Rockwell hardness”, and the Rockwell scale designation, which shows the load applied on the .

Rockwell hardness (Rc) refers to a method for measuring the hardness of a material, primarily metals, using an indentation test. It is named after the Rockwell scale, which was developed . HV, HB, HRC Hardness Comparison Chart. Hardness testing is the simplest and most straightforward method among mechanical property tests. In order to replace certain mechanical property tests with hardness tests, a .A Vickers hardness tester. The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. [1] The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter . Related reading: Metal Hardness Comparison Chart: HV, HB, HRC Commonly Used Hardness Brinell Hardness. The Brinell hardness test uses a ball made of hardened steel or a hard alloy with a diameter of D as the .

HRC (Rockwell C Hardness) and HRB (Rockwell B Hardness) are scales measuring material hardness; HRC is used for harder materials, HRB for softer materials. Key Differences. HRC, or Rockwell C Hardness, measures the hardness of harder materials like steel. HRB, or Rockwell B Hardness, is used for softer materials, such as non-ferrous metals. .Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find qualitative relations to other material properties (e.g., strength, stiffness, density) or to the material behavior under certain stresses (e.g., abrasion .

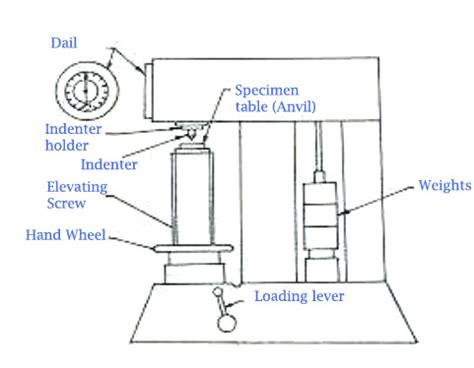

rockwell hardness test diagram

International Standards Organization (ISO 6508-1 Metallic Materials) – Rockwell Hardness Test Part 1; American Standard Test Method (ASTM E 18) – Rockwell Hardness and Rockwell Superficial Hardness of Metallic Materials . Example 1: A regular Rockwell hardness method (HRC) 45 HRC. The number 45 represents the hardness value of the material. The Rockwell scale was cocreated by Hugh and Stanley Rockwell in the early 20th century to test the hardness of different materials. There are several different scales by which a material’s hardness is measured on, but blade steels are measured on the C scale. . (HRC means Hardness on Rockwell scale C.) To find the value, a diamond-tipped .Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learn more about hardness testing basics here. The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and .TableofContents ListofFigures ix ListofTables xii 1.Introduction 1 2.RockwellHardnessTest 2 2.1Significanceofthetest 2 2.2Rockwellindentationtestprinciple 2 2 .

runnig compression test

Some tests, like the Vickers hardness test, can be used on a macro scale as well as a micro scale. The loads required are listed in Table 1 below: Table 1: Different Hardness Test Methods and Their Corresponding Loads. Method Load Range Standard; Method. Brinell. Load Range. 1 kgf–3,000 kgf. Standard. ASTM E10, ISO 6506. Method.The result is a dimensionless number noted as HRA, HRB, HRC, etc., where the last letter is the respective Rockwell scale. . The various indenter types combined with a range of test loads form a matrix of Rockwell hardness scales that are applicable to a wide variety of materials. Rockwell B and Rockwell C are the typical tests in this facility.

Any value ranging in the mid-50s and above on the HRC hardness scale is considered hard. However, a high Rockwell hardness HRC number doesn’t necessarily mean it’s the best metal for a particular application. Superficial Scales. The Rockwell Hardness Test also uses superficial scales. These use lower loads and shallower indentions and are .

running a compression test

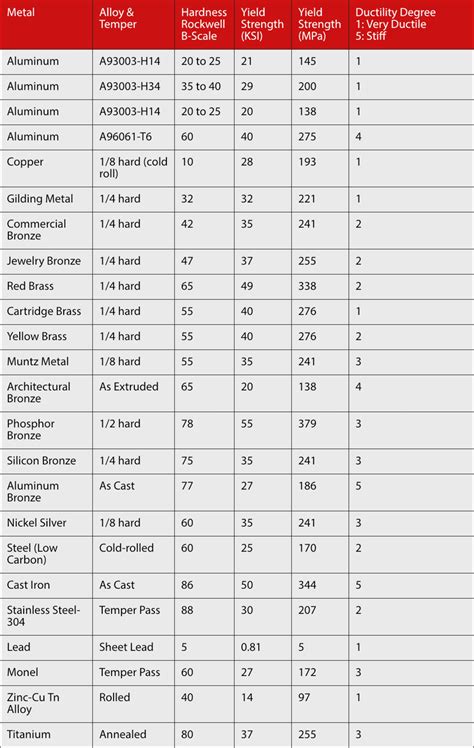

rockwell hardness chart for metals

However, the division of the degrees of hardness in steps of 0.002 mm is maintained. This results in hardness values in the theoretical range of 0 (full indentation depth to 0.26 mm) to 130 (no indentation depth) when using carbide balls. When using a carbide ball for hardness testing, a main distinction is made between process variants B and F.Before application of the Rockwell hardness test, you must prepare the surface of the material to be tested. The required surface condition for the Rockwell hardness test depends on the load used. The Rockwell hardness test is .The Vickers hardness test method was developed by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers hardness test method can .

Mohs hardness kit, containing one specimen of each mineral on the ten-point hardness scale. The Mohs scale (/ m oʊ z / MOHZ) of mineral hardness is a qualitative ordinal scale, from 1 to 10, characterizing scratch resistance of .

The Rockwell hardness value is expressed as a combination of a hardness scale symbol and a hardness number. For example, HRC 55 indicates a hardness of 55 on the Rockwell C scale. The test procedure involves the following steps: Application of preliminary load: A preliminary load is applied to ensure proper seating of the indenter. For example, “HRC 96” means 96 on the Rockwell C scale. Rockwell hardness numbers are usually used to describe the hardness of metals, although they are also used for some plastics. Like the Brinell hardness scale, the Rockwell scale is based on measuring the depth of the indentation made by pressing a diamond point, or a ball, into the .Guides to Hardness Testing. . In this test method, the minor (preload) is always 10 kgf. The major load may be any of the following loads: 60 kgf, 100 kgf, or 150 kgf. Superficial Rockwell Testing. . Repair Return Form ABOUT US. About Us Welcome to .

Overall, hardness is a significant factor you need to consider when selecting the most suitable materials for a particular purpose. To determine a hardness value, you can perform several tests, including the Rockwell Hardness Test, the Brinnel Hardness Test, Microhardness, Knoop, Vickers, and the Superficial Rockwell.

HRC Rockwell Test - DIY Hardness TestUsually, harder steel increases the likelihood that blade will remain sharp for a longer period of time. Steel hardness . Mohs hardness test uses 10 reference materials of varying hardness as the scale for the test. The softest material used is talc (value=1) and the hardest material is diamond (value=10). Given that the references used for the Mohs scale do not have a graded increase, the Mohs scale lacks accuracy and is only a rough measure of hardness.

The Brinell hardness is designated by the most commonly used test standards (ASTM E10-14 [2] and ISO 6506–1:2005) as HBW (H from hardness, B from brinell and W from the material of the indenter, tungsten (wolfram) carbide). In former standards HB or HBS were used to refer to measurements made with steel indenters. The NIST HRC levels establish the hardness of materials slightly harder than the historical standards used in the United States for the past 75 years. . The use of tungsten carbide balls will provide an improvement to the Rockwell hardness test because of the tendency of steel balls to flatten with use, which results in an erroneously .A widely used variant of the Rockwell hardness test is the superficial Rockwell test, wherein the minor load is 3 N and the major loads are 15, 30, or 45 N.Further details on the Rockwell superficial hardness scales are available in the relevant ASTM standards (ASTM 1984).The Rockwell hardness values are expressed as a combination of hardness number and a scale .1. Introduction. Rockwell hardness is an ordinal quantity measurement and is therefore dependent on a defined test method. In today’s international commerce, Rockwell hardness testing is almost exclusively conducted in compliance with the test methods specified by ASTM-International (test method ASTM E18) [] or the International Organization for Standardization .

rockwell hardness c scale chart

Rekkyō Sensen Manga - Read Manga Online Free. Releasing. Rekkyō Sensen; Guerra das Grandes Potências • The Doomsday is Wartime • Rekkyō Sensen. Start ReadingRead .

hardness test hrc full form|how to calculate rockwell hardness